In today’s industrial landscape, field service operations and predictive maintenance are critical components of operational excellence. Organizations are constantly seeking ways to reduce downtime, optimize maintenance schedules, and improve technician efficiency. The challenge has always been finding the right balance between proactive and reactive maintenance while managing costs and resources effectively.

The emergence of Generative AI (GenAI) presents a compelling opportunity to transform how we approach these challenges. But can GenAI truly revolutionize field service and predictive maintenance, or is it just another technology trend that promises more than it delivers?

Here’s what we’re learning from the front lines of GenAI implementation in industrial maintenance.

What are Field Service and Predictive Maintenance?

Before we explore how GenAI can transform these areas, let’s quickly clarify what we’re talking about:

- Field Service: This refers to the service technicians who maintain, repair, and install equipment at customer sites or remote locations. It involves scheduling, dispatch, parts management, and knowledge sharing among technicians.

- Predictive Maintenance: This is a maintenance strategy that uses data analysis tools and techniques to detect anomalies in equipment operation and potential defects, enabling maintenance to be scheduled at the most opportune time—before equipment failure occurs.

Both areas generate massive amounts of data and require sophisticated decision-making, making them prime candidates for AI transformation.

The GenAI Opportunity

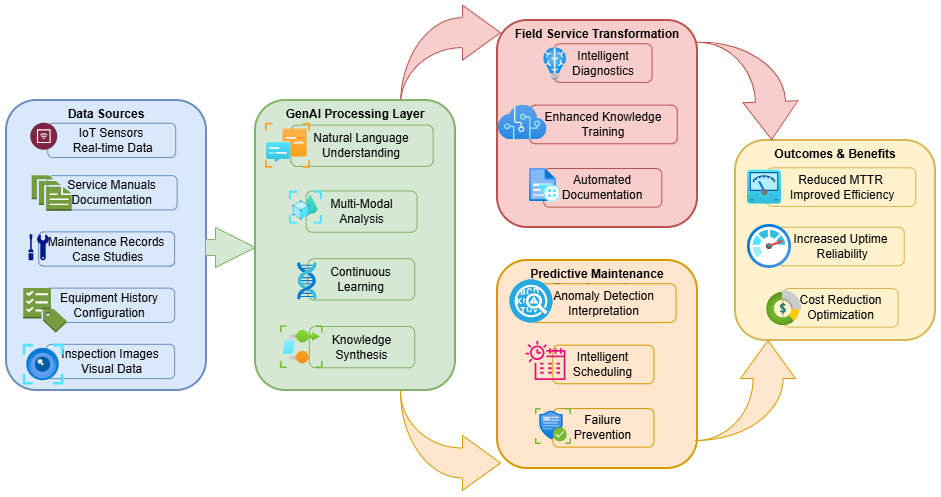

Generative AI brings unique capabilities to the table: it can understand natural language, generate human-like responses, learn from vast amounts of unstructured data, and assist with complex problem-solving. These capabilities align perfectly with the challenges faced in field service and predictive maintenance.

Here’s how GenAI is beginning to reshape these domains:

- Natural Language Interaction: Technicians can describe issues in plain language, and GenAI can help diagnose problems, suggest solutions, and guide repair procedures.

- Knowledge Synthesis: GenAI can analyze thousands of service manuals, maintenance records, and case studies to provide contextual recommendations.

- Predictive Insights: By processing historical maintenance data alongside real-time sensor readings, GenAI can identify patterns that humans might miss.

- Automated Documentation: GenAI can automatically generate service reports, maintenance logs, and recommendations based on technician inputs.

Transforming Field Service with GenAI

Field service operations have traditionally been reactive and heavily dependent on individual technician expertise. GenAI is changing that dynamic.

1. Intelligent Diagnostics and Troubleshooting

- The Challenge: When equipment fails in the field, technicians often rely on experience and intuition to diagnose issues. This can lead to longer resolution times, multiple site visits, and unnecessary parts orders.

- The GenAI Solution:

- Conversational Diagnostics: Technicians can describe symptoms, error codes, or unusual behaviors to a GenAI assistant in natural language. The AI can ask clarifying questions, cross-reference similar cases, and suggest diagnostic steps in real-time.

- Context-Aware Recommendations: GenAI can analyze the equipment’s service history, similar cases from other sites, and manufacturer recommendations to provide targeted troubleshooting guidance.

- Reduced Mean Time to Repair (MTTR): By accelerating the diagnostic process, GenAI helps technicians identify and resolve issues faster, reducing downtime and improving customer satisfaction.

2. Knowledge Management and Training

- The Challenge: Service knowledge is often scattered across manuals, internal databases, and individual technician experience. New technicians face a steep learning curve, and knowledge transfer can be inconsistent.

- The GenAI Solution:

- Intelligent Knowledge Base: GenAI can synthesize information from service manuals, maintenance records, manufacturer documentation, and internal knowledge bases into a unified, searchable resource.

- On-Demand Training: Technicians can ask GenAI questions about procedures, parts, or best practices and receive instant, contextual answers. This reduces the need for extensive formal training while improving knowledge retention.

- Best Practice Sharing: GenAI can identify and share successful resolution strategies from across the organization, helping all technicians benefit from collective experience.

3. Automated Service Documentation

- The Challenge: Creating detailed service reports is time-consuming and often incomplete. Technicians may skip documentation to save time, leading to gaps in service history.

- The GenAI Solution:

- Voice-to-Report: Technicians can dictate their findings and actions during or after a service call, and GenAI can automatically generate structured service reports, including parts used, time spent, and recommendations.

- Consistency and Compliance: GenAI ensures all reports follow a standard format and include necessary details for compliance and future reference.

- Freeing Up Time: By automating documentation, technicians can spend more time on actual maintenance work, improving productivity.

Revolutionizing Predictive Maintenance with GenAI

Predictive maintenance has relied heavily on data analytics and machine learning models. GenAI adds a new dimension by bringing interpretability, natural language insights, and adaptive learning to the equation.

1. Enhanced Anomaly Detection and Interpretation

- The Challenge: Traditional predictive maintenance models can identify anomalies but often struggle to explain why they occurred or what actions should be taken. This “black box” problem makes it difficult for maintenance teams to trust and act on predictions.

- The GenAI Solution:

- Explainable Predictions: GenAI can analyze sensor data, identify anomalies, and explain in plain language what’s happening, why it might be concerning, and what could be causing it.

- Multi-Modal Analysis: GenAI can process not just sensor data, but also images from inspections, maintenance notes, and historical patterns to provide a comprehensive view of equipment health.

- Actionable Insights: Instead of just alerting that something is wrong, GenAI can suggest specific maintenance actions, recommended parts, and optimal scheduling based on current workload and criticality.

2. Intelligent Maintenance Scheduling

- The Challenge: Balancing maintenance needs with operational requirements is complex. Scheduling too early wastes resources; scheduling too late risks failures. Optimizing across multiple pieces of equipment and limited technician availability adds further complexity.

- The GenAI Solution:

- Context-Aware Scheduling: GenAI can consider equipment criticality, predicted failure timelines, available technician skills, parts inventory, and production schedules to recommend optimal maintenance windows.

- What-If Scenarios: Maintenance planners can ask GenAI questions like “What if we delay maintenance on this unit for two weeks?” and get detailed analysis of risks, resource implications, and alternative approaches.

- Dynamic Rescheduling: As new data comes in or priorities shift, GenAI can automatically adjust maintenance schedules and communicate changes to relevant stakeholders.

3. Proactive Failure Prevention

- The Challenge: Even with predictive maintenance, unexpected failures can occur due to complex interactions between components, environmental factors, or usage patterns that traditional models don’t capture.

- The GenAI Solution:

- Pattern Recognition: GenAI can identify subtle patterns across multiple equipment units, sites, or time periods that indicate emerging failure modes before they become critical.

- Root Cause Analysis: When failures do occur, GenAI can analyze maintenance history, operating conditions, and component relationships to identify root causes and prevent recurrence.

- Continuous Learning: As GenAI processes more data from successful maintenance interventions and failures, it continuously refines its predictions and recommendations, becoming more accurate over time.

What We’re Learning: Challenges and Considerations

While the potential of GenAI in field service and predictive maintenance is exciting, our early implementations have revealed important considerations:

1. Data Quality Matters

GenAI is only as good as the data it learns from. Incomplete service records, inconsistent documentation, or poor sensor data quality can lead to inaccurate recommendations. Organizations need to invest in data quality initiatives alongside GenAI implementation.

2. Trust and Adoption

Technicians and maintenance teams need to trust AI recommendations. This requires transparency in how GenAI arrives at its conclusions and clear protocols for when human judgment should override AI suggestions. Training and change management are crucial.

3. Integration Complexity

GenAI systems need to integrate with existing CMMS (Computerized Maintenance Management Systems), ERP systems, sensor networks, and service management platforms. Seamless integration is essential for real-world effectiveness.

4. Regulatory and Safety Considerations

In safety-critical industries, AI recommendations must be validated and approved by qualified personnel. Clear governance frameworks are needed to ensure AI-assisted decisions meet regulatory and safety standards.

5. Cost-Benefit Analysis

GenAI implementation requires investment in infrastructure, training, and ongoing maintenance. Organizations need to carefully evaluate ROI, considering not just direct cost savings but also improved uptime, customer satisfaction, and technician efficiency.

The Bottom Line

The question “Can GenAI transform field service or predictive maintenance?” is increasingly being answered with a qualified “Yes.” Early adopters are seeing significant improvements in diagnostic accuracy, maintenance efficiency, and technician productivity.

However, successful transformation requires more than just deploying GenAI tools. It requires:

- Strategic Vision: Clear understanding of where GenAI can add the most value

- Data Foundation: High-quality, accessible data for training and operation

- Human-AI Collaboration: Thoughtful design of workflows that leverage both AI capabilities and human expertise

- Continuous Improvement: Iterative refinement based on real-world performance and feedback

GenAI won’t replace skilled technicians or maintenance professionals. Instead, it will augment their capabilities, making them more efficient, effective, and able to focus on high-value work that requires human judgment and expertise.

As we continue to learn from implementations across different industries and use cases, one thing is becoming clear: organizations that embrace GenAI thoughtfully and strategically will gain a significant competitive advantage in field service and predictive maintenance.

How is your organization exploring GenAI in field service or predictive maintenance? What challenges or opportunities are you seeing?

What soft skills have been most valuable in your leadership journey? Share your thoughts below.